The Challenge.

A well-established customer was looking to cut costs, rationalise their packaging range, and reduce the annual weight of polythene used across 15 processing sites in the UK.

Their operations had grown organically, resulting in a fragmented, decentralised approach to packaging procurement. Each site ordered independently, creating a large and inconsistent SKU range, unnecessary duplication, and missed opportunities for optimisation.

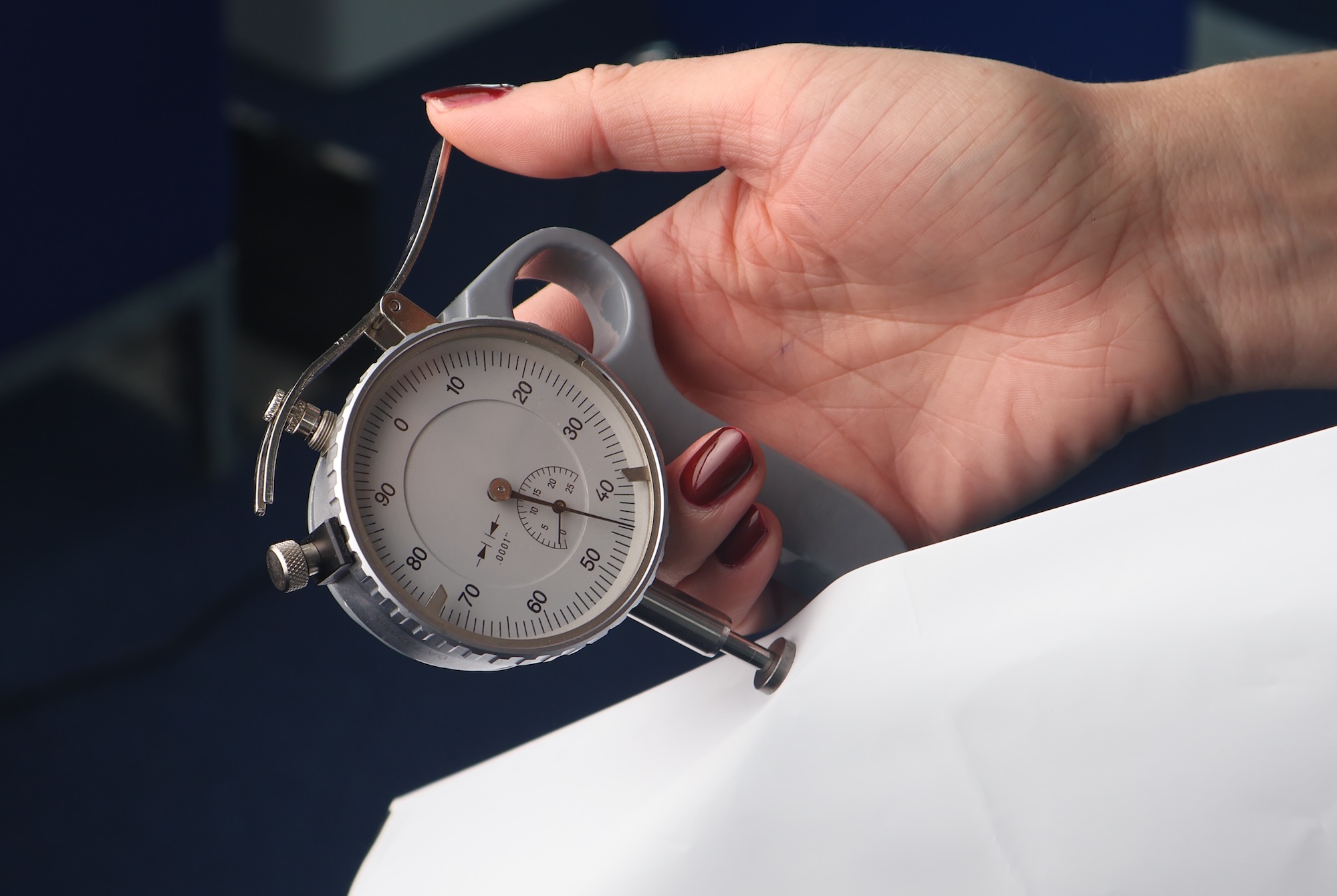

Recognising the scope for improvement, we conducted on-site Application Audits of their products and processes, which would identify opportunities to rationalise, reduce polythene usage, stock holding and deliver significant cost savings.